Enhance Efficiency with Effective Inventory Management

March 21, 2023

Did you know that 74 per cent of products going into inventory never sell, even after six months? What you would do with a tool to avoid that?

Inventory management today is not easy to plan, in this article we will tell you what techniques and programs help plan inventory. Please read further and figure out what you could change in managing your inventory today!

The Importance of Inventory Control

Efficient inventory control is important to effective inventory management. It represents all the measures and systems put in place to control and record inventory levels adequately. Small companies need to be up to date with inventory control to ensure that they can operate smoothly and meet customer needs.

Another major advantage of strictly enforced inventory control is eliminating the occurrence of stockouts, whereby the shortage of product would occur from businesses not having enough of a specific item in stock to satisfy customer demand, resulting in lost sales and unsatisfied customers. By encouraging the tracking of inventory quantities and the application of optimal reorder points, companies can ensure they do not run dangerously low of stock for its most critical items.

Preventing excess inventory

Furthermore, efficient inventory control also precludes overstocking. Overstocking is storing more inventory than might be required or is needed for customers’ purchases or for business operations. It is tied up in valuable resources like warehouse space or cash for purchase. It can also result in higher carrying costs, including the potential costs of goods obsolescence. Implementing inventory control measures can allow businesses to accurately forecast demand, adjust their purchasing decisions accordingly, and avoid overstocking.

In addition, strong inventory control helps to optimise the flow of cash. By managing inventory levels, and having a good idea of future demand, businesses can reduce the capital sum invested in excess inventory. The freed cash may then be channelled to improve business in other areas, for example by investing in marketing or product development.

Inventory Optimization Techniques

For that reason, optimising inventory levels is vital to businesses in order to improve operational efficiencies as well as maximise financial performance. Applying advanced analytics and forecasting tools, a business can manage inventory levels effectively so that they satisfy customer demand and lower inventory carrying costs, thereby optimising its supply chain performance.

One way to do this is by using demand forecasting models, which can predict future demand by considering historical data, market trends, and other relevant variables. For example, a demand forecasting model could predict that supermarkets will be selling 10 times more milk during the Christmas period. By using the prediction to order more milk, supermarkets should be able to significantly reduce stockouts and improve customer satisfaction.

JIT Inventory Management

A second option is using just-in-time (JIT) inventory. JIT is a purchasing system in which a business receives the products it needs from a supplier only when it is required in the production process or before selling it to a customer. If a business doesn't hoard or hold too much capital in inventory, they can use the profits from reduced holding costs to reinvest in growth of the enterprise. In JIT, a business would have to share more information with its supplier to track their capacity and ability to supply goods in a more timely manner. This also helps enterprises to hold their inventories at minimal levels.

Furthermore, firms can use so-called safety stock strategies to mitigate demand and supply uncertainty. Safety stock is the amount of extra inventory kept on hand as a buffer for unforeseen loss for the supply chain, such as a late supplier shipment or increased demand to satisfy customers – in other words, it’s an insurance policy. The demand and uncertainty involved determines the optimal safety stock level.

ABC Analysis

Besides, ABC analysis is one of the ways to optimise inventory. In this classification of inventory articles, according to their value and turnover, there are A-items — high-value items with low use; B-items — low-value items with the same frequency of use as A-items; C-items — low-value items with high usage.

Through this sorting, businesses can focus on costly items on which they want to do a good job in their inventory management, placing the right amount, and not too little, on the shelves to avoid stockouts of these crucial products.

Inventory optimisation methods such as demand forecasting, JIT inventory management, safety stock methods, and ABC analysis are crucial for balance between supply and demand. This leads to optimal inventory turnover, reducing cost of stock, increasing revenue and enhancing supply chain performance overall.

Streamlining Business Processes

Inventory management encompasses the process of converting work-in-progress into finished goods as effectively as possible. By fine-tuning every single step in the supply chain, companies can slowly eliminate any inefficient bottlenecks, automate mundane and repetitive tasks, and increase overall productivity. In turn, this translates to achieving higher efficiency, shorter lead times, and happier customers.

One of the primary step in streamlining process for business is Order Processing. It deals with automated order and system by automating the order-entry process. It includes capturing order enquiries and placing the order with the customer. Organisations also use this concept to cache and acknowledge orders using it. Automating order entry helps to reduces the manual errors eliminating data entry mistakes, order processing cycle and order delivery filled without any missing part. This helps to deliver orders faster to customers, and reduces the cycle.

Warehouse management

Another is warehouse effectiveness and the logistics chain, where installing a barcode or radio-frequency identification (RFID) system can give a real-time view of inventories, their locations and movements, enabling better visibility, optimised movement, minimising picking errors and time-to-ship for orders.

Optimising logistics, such as the identification of the most efficient routes and the management of means of transportation, allows its users to accomplish the same goal in a shorter time.

Furthermore, ranging technology (increasing offerings) – such as automatic receiving and inventory storing systems – can improve efficiency and effectiveness of stocking. Retailers can leverage automation and innovation to interpret, sort, and store items to reduce time spent on manual tasks and, overall, improve accuracy. These features help fasten replen coming in, allowing businesses to keep well-stocked shelves and reduce lead times at the same time.

Leveraging Technology for Efficiency

Modern technology plays an important role in inventory management. Among the many benefits, businesses will be able to manage their inventory smarter, improve business efficiency and have better control over their performance. It also offers crucial competitive edge for business and leads to significant productivity and cost savings of the businesses utilizing it.

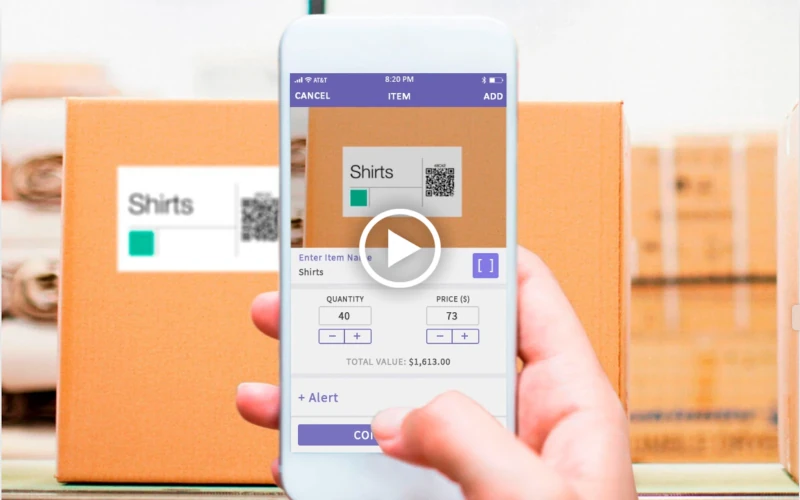

The barcode has brought about one of the most revolutionizing technologies of inventory management. With barcodes, each product has been assigned with a unique identifier, which has made the tracking and management of stock easier compared to earlier times. By the use of hand-held devices that can read barcodes, businesses can enter their inventories easily, conduct stock counts, dispatch orders and fulfil all their inventory-related activities quickly and efficiently. As a result, the inventory-related processes have got faster, with minimal errors and more accuracy.

RFID Systems

Radio-frequency identification (RFID) tags are a technology that augments inventory management. These tags hold electronic information that can be read at a distance with RFID scanners, and thus aid in the creation of real-time, automated, inventory visibility without the use of a barcode scanner. Moreover, RFID systems can improve business, and increase general supply-chain efficiency.

Inventories are a modern import that provides very real benefits but can also cause trouble. Cloud-based inventory management systems are replacing stand-alone systems for companies of all sizes. They provide a single point of access for inventory information, real-time updating, and increased ease of integration with primary business systems such as point of sale (POS) and enterprise resource planning (ERP).

With the help of cloud-based inventory management, businesses can now monitor critical inventory information whenever and wherever they are, to make the right decisions and optimise operations.

To learn more about why an inventory management system is important today, please check out our page that shows the importance.