A step-by-step guide to Inventory List Automation

July 8, 2024

Automation of inventory lists is the central step towards complete inventory automation. That is using special software and related technology, such as QR codes to track, analyze, and control inventory items.

Automating an inventory list can reduce errors, streamline operations and save time. Here's a step-by-step guide to help you plan automation of your inventory list management:

1. List Your Requirements:

-

Determine the size and scope of your inventory, what information you want to have on your automated list.

-

Decide how you want to update the data on your inventory list.

-

Identify any specific requirements (e.g., tracking, alerts, reporting, user access levels).

-

Identify what existing systems you want your Inventory Management system to be integrated and share data with.

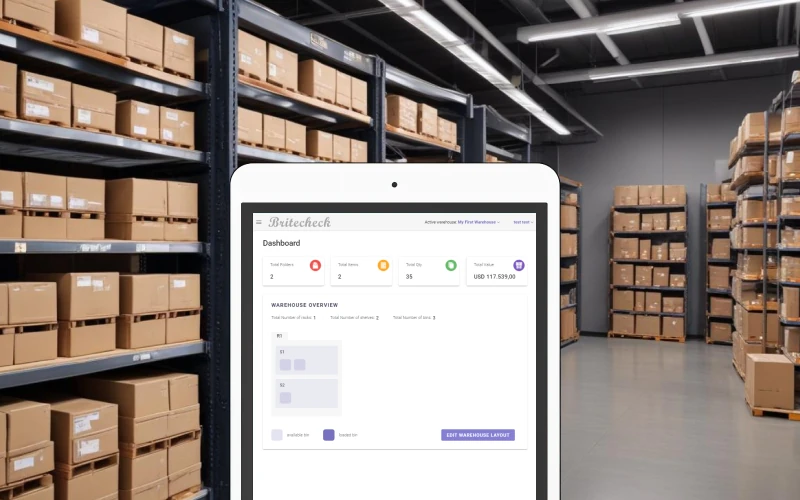

2. Select Inventory Management Software:

-

Based on your requirements, research and select a suitable inventory management software.

3. Set Up the Software and Input Initial Inventory Data:

-

Install the software on your system or access it via the cloud, create user accounts and assign data access permissions.

-

Enter information about your current inventory into the software manually or via bulk import (e.g., CSV file).

-

Reconcile inventory data in your new automated list with the old list and the actual inventory.

4. Configure Inventory Parameters, Set Up Reports, Alerts and Notifications:

-

Define categories and subcategories for better organization.

-

Set parameters and configure alerts for low stock levels, reorder points, and expiry dates.

-

Schedule automatic reports for stock levels, sales trends, and order history.

5. Integrate QR Code/Barcode Technology and Automate Data Collection:

-

Implement QR code scanning, introduce barcode or RFID scanners for data entry and tracking.

-

Label all inventory items with QR codes, barcodes or RFID tags.

-

Use scanning to automatically update inventory levels when receiving or issuing items.

-

Link the software to your sales and purchase systems for real-time updates.

6. Train Staff:

-

Provide training sessions for employees on how to use the new system. Create cheat sheets and how-to guides.

-

Assign the product expert and make sure that everyone knows how to reach out for help.

7. Collect and analyze performance data:

-

Setup processes to continuously monitor the system's performance.

-

Regularly collect user's feedback and make adjustments.

By following these steps, you can effectively automate your inventory list management, leading to a number of great benefits to your business.

7 Reasons to Automate your Inventory Lists

Increased Accuracy

One of the primary features of automation, as compared with complicated manual tracking of stock, is the reduction of human error. Inventory can be tracked manually, but humans are prone to making mistakes. A calculator can make the same mistake as a human. The difference is that an automated system will have exact data showing current stock levels, real time, giving accurate information, whereas a human would have to type in numbers and possibly make a mistake, typing an extra zero or forgetting something.

Time and Effort Savings

The advantage of automating inventory processes is that it saves a lot of time and effort. Therefore, employees can concentrate on other more important issues, such as sale trends or customer service.

Improved Stock Control

Automated systems give businesses greater control over their stock by providing instant information about what is available and where, which can help them keep the right levels of stock and avoid both stockout (not having any stock at all) and overstock (having stock where there is no demand).

Enhanced Inventory Turnover

Real-time data from automated systems also affects inventory management. With valid, real-time transactional information, businesses can track speed of sale and pinpoint slow-moving inventory, allowing companies to restock frequently and better find ways to move slow-moving goods. Turnover rates should then increase dramatically.

Lower Carrying Costs

Through accurate and granular tracking, management can reduce the level of inventory they need to carry – helping to cut costs such as warehousing, insurance and manning costs. Automation can help keep stock levels at their optimal efficiency, keeping your money working for your business rather than being tied up in unsold stock.

Better Data Analysis and Reporting

With automated inventory systems, you get effective and adequate analytics and reporting features. They provide you with the reports to gauge inventory performance, sales trends and the predictive analytics of the demand for items. This gives insights to businesses on better purchasing and production strategies that streamline the overall operations.

Simplified Tax Compliance

Accurate inventory records are also required for tax purposes. An automated system allows the shop to make an accurate survey of its inventory at the end of the year, facilitating the calculation of COGS and other tax-related metrics. Furthermore, the automated system allows the shop to satisfy this tax requirement more accurately, giving the business a better chance to avoid fines for a failure to abide by the regulations.

Get a demo to learn about Britecheck inventory management.