Simplify Your Business Operations: Best Inventory Tracking Methods for Small Business Owners

June 18, 2024

Efficient operation is key in any kind of business, big or small. Running business smoothly is also a significant factor in your success or failure. Among the key problem that every business owner face is: “What are the best methods in tracking inventory?”

Inventory, it is warehoused items that a business sells to make a profit while keeping minimum quantity of crazily priced items. Sometimes, it is a time-consuming and difficult job to track your inventory.

Using the right method will make the process smooth, faster and easier.

Best Inventory Tracking Methods for Small Business

Here are some of the top inventory tracking techniques that are proving their worth especially for small business owners.

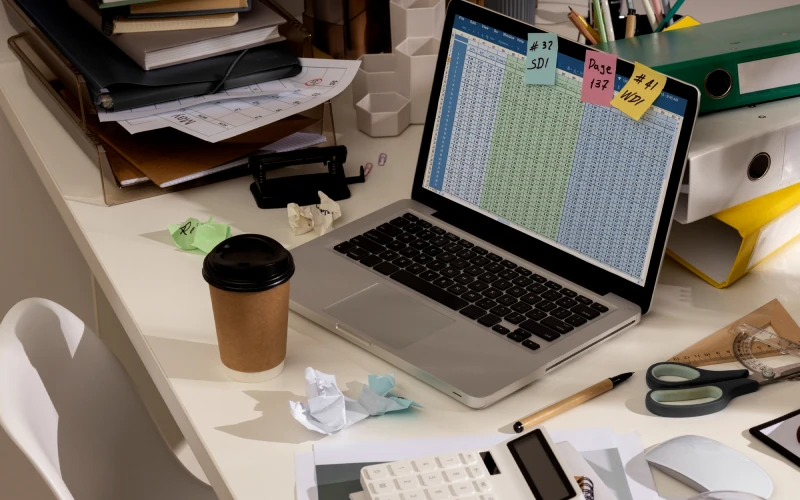

Spreadsheets

Totally vintage! Sometimes, it may look like spreadsheets are from the Jungle Book, but those are often exactly what's needed for small businesses. Basic programs contained in Excel or Google Sheets allow you to build your own, customised templates for stock, inventory, orders and sales. Formulas and functions let you automate many numerical recurring operations – such as counting, adding or multiplying, and automatically updating your inventory when something is sold (real-time). Spreadsheets are a very low-cost (or zero-cost, in the case of free programs) solution for businesses that keep the costs low and their inventory somewhat simple.

Barcode Systems

If your inventory volume is large enough that you need to take the process of inventory tracking to another level, you might want to consider barcode systems that could help with efficiency and accuracy. All you need to do is to get your each product assigned with a unique barcode with the use of a barcode scanner and inventory management software, so you could track every movement of your products, from the time they enter your warehouse until the time they leave.

That's because these systems greatly simplify processes, cut down on human error, and on top of that offer on-demand reports about exactly how much stock you have in any given area. There is often an upfront cost needed to acquire equipment and software, but for many small businesses, the long-term value outweighs the cost.

RFID Technology

Radio-frequency identification (RFID) technology is an effective and advanced option for the method of tracking inventory. The tags in such a system contain electronic information, and the RFID readers do not require a line-of-sight for the tag, unlike barcode systems. While the implementation of the RFID process to track inventory in a warehouse setting may be more expensive than other methods, it will bring significant cost and time savings in the long run for large warehouses size. Is it a good warehouse for business?

See our analysis!

Consideration of cost and time saved, while choosing an inventory tracking method, is always an important thing for factory owners or small business owners.

Strategy to save labor and cost in a manufacturing company

To track and manage inventory, computer software, and databases represent an excellent tool for small business owners since they provide data on the quantity of a specific item in stock, as well as useful insights on sales and consumption, keeping track of sales trends, and procuring more when stock is running low.

Some features such as real-time tracking, automated alerts, and customizable reports provide valuable information that the business owner previously would seek from financial reports and help him take control and optimize his inventory, in such a way that these features reduce potential errors, enhance overall efficiency and provide him with a whole new level of resiliency on monitoring the condition of his inventory. Maybe it takes time to get familiar with how to operate the new software when deciding to buy the right inventory management software for your operation. Still, the time and capital saved in the long run may justify the purchase decision for many small businesses.

Conclusion

Good inventory tracking is an instrumental tool for small business owners, helps streamline business operations, reduce overhead costs as well as enhance customer satisfaction. And here is a final tip, when it comes to selecting and applying the right methods for inventory tracking in your factory, it is important to consider the time and labor that you would like to save, money will be invested at the beginning, and time and labor are required to have the system set up. Make a balance between cost-benefit when considering the pros and cons of each method, and how well the world is suited to the needs and specifics of your operation.

By doing an evaluation of your specific inventory tracking needs and investing in the right tools, you can achieve your business goal and create a sustainable growth path that will contribute to the future prosperity and financial well-being of your business. With an investment of time to understand the basics of effective inventory tracking and consistently carry out such practices for your small business or workplace, you can help ensure a bright future for your business outlet, giving the right amount of attention to your bottom line, so it will remain wealthy and prosperous.